Post-harvest fungicides such as imazalil (Magnate or Fungaflor) play an important role in controlling post-harvest decay such as green and blue mould and are essential for the storage and marketing of citrus.

However, the continued use of these post-harvest fungicides without proper management allows for the build-up of fungicide resistant decay spores within a pack house, particularly if pack house hygiene is poor.

Over time this can lead to a situation where the decay fungus is able to grow on fungicide treated fruit, resulting in the growth of the decay and fruit breakdown in the market.

This resistance to the fungicide is a serious and important post-harvest problem, which needs to be managed in the packinghouse to minimise any potential post-harvest losses and claims.

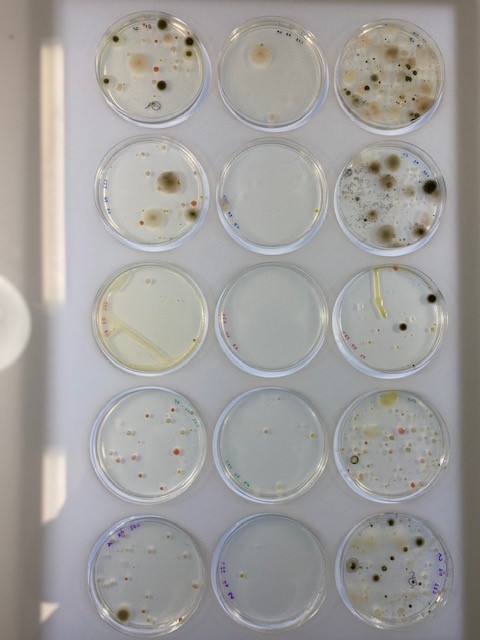

The Postharvest Sanitation and Fungicide Resistance Service is a not-for-profit service which looks for the presence of decay-causing fungi in the packinghouse and identifies if these decay-causing fungi have any technical resistance to common postharvest fungicides.

The results from last season showed there were large differences observed in the levels of sanitation and technical resistance to post-harvest fungicides between the different packinghouses around Australia.

Some good packinghouses, such as Packinghouse A, had very low levels of general moulds and decay in the packinghouse with no detectable technical resistance to any postharvest fungicide.

This was a very good result and showed that with good packinghouse hygiene and fungicide management, potential fungicide resistance can be eliminated.

The results from Packinghouse B showed that while there were higher levels of green and blue mould spores detected in their packinghouse, there was no technical resistance detected.

This showed that the post-harvest fungicides were effective in controlling these decay fungi during storage.

However, the results from Packinghouse C showed that while the levels of green and blue mould were similar to Packinghouse B, there was the start of some technical resistance to TBZ (Vorlon or Tecto) fungicide starting to develop (as indicated with the growth of green and blue mould spores on the TBZ amended agar plates).

This needs to be managed and monitored, as any increase in technical resistance will reduce fungicide efficacy.

This was illustrated in the results from Packinghouse D and E, where there were high levels of green and blue mould in the packinghouse, which also contained high levels of technical resistance to TBZ.

Some of the key management factors in reducing the risk of fungicide resistance include:

• Monitor fungicide resistance: The early detection of resistance increases the chance that its development can be managed and stopped. It is therefore critical to measure and monitor both packinghouse sanitation and hygiene, and the levels of technical resistance to postharvest fungicides.

• Optimise fruit health: Good post-harvest practice to minimise physical damage to the fruit during harvest and handling.

• Use best hygiene practices: Lowering the populations of decay-causing spores in the packinghouse, cool room and on the fruit are keys to a successful management program. This includes removal of rotten fruit from the packinghouse and cool rooms, and the regular sanitation of equipment, cool rooms and packing line by washing (or using fogging technology).

• Optimise fungicide use: Understand the way each fungicide works to develop strategies to minimise the development of resistance by using rotations and mixtures whenever possible and before resistance selection occurs.

• Optimise fungicide efficacy: The correct fungicide concentration and coverage determines the efficacy of the treatment and minimises the chances of decay spores surviving following treatment.

This is a problem as the continued use of TBZ will make its use ineffective in controlling green and blue mould.

While TBZ can be an effective fungicide for the control of sensitive strains of green and blue mould, it also has the additional benefit of assisting with reducing the expression of chilling injury.

This additional benefit of TBZ, especially hot TBZ application, is one of the few postharvest treatments that is available to suppress chilling injury during cold treatment for export.

Therefore, it is important to properly manage TBZ in the packinghouse to maintain its fungicide efficacy and to ensure resistance does not get out of control.

Fortunately, in the 2021 season, no technical resistance to fludioxonil or pyrimethanil was detected in any of the tested packinghouses at this time.

Technical resistance to TBZ fungicide was observed to be common across many packinghouses (63 per cent of all samples).

However, technical resistance to imazalil was less common (13 per cent of all samples) but technical resistance to imazalil is problematic and requires active attention.

Imazalil is a mainstay of many citrus post-harvest fungicide programs and its efficacy needs to be actively managed to maintain control of postharvest decay.

The levels of technical resistance to imazalil which was identified in Packinghouse F was a concern as these moderate levels can quickly develop into more severe levels of technical resistance (Packinghouse G).

These very high levels of technical resistance to both TBZ and imazalil in Packinghouse G were of high concern and active management was required to start to slow, stop and reduce this development of fungicide resistance.

Reducing fungicide resistance in packinghouses with such high levels of technical resistance is a long and slow process of cleaning and fungicide rotations.

The best solution to managing resistance is to prevent it from occurring.

This management of resistance to post-harvest fungicides requires a whole-of-system approach, starting from harvest through to packing and storage. However, the first step of managing resistance is knowing what is happening in the packinghouse, by monitoring for technical resistance.

– John Golding and Mark Bullot, NSW DPI